Why You Destroy Your Vacuum Pump and 1 way to fix it.

The T209 rice test is the worst possible situation for a vacuum pump. By design, vacuum pumps need to be free of contaminants and never EVER allow water in.

So what do we do? We put a container of water and hook it up in line with our pumps. Because we don’t have time to care about a vacuum pump and have more tests to run than there are hours in a day.

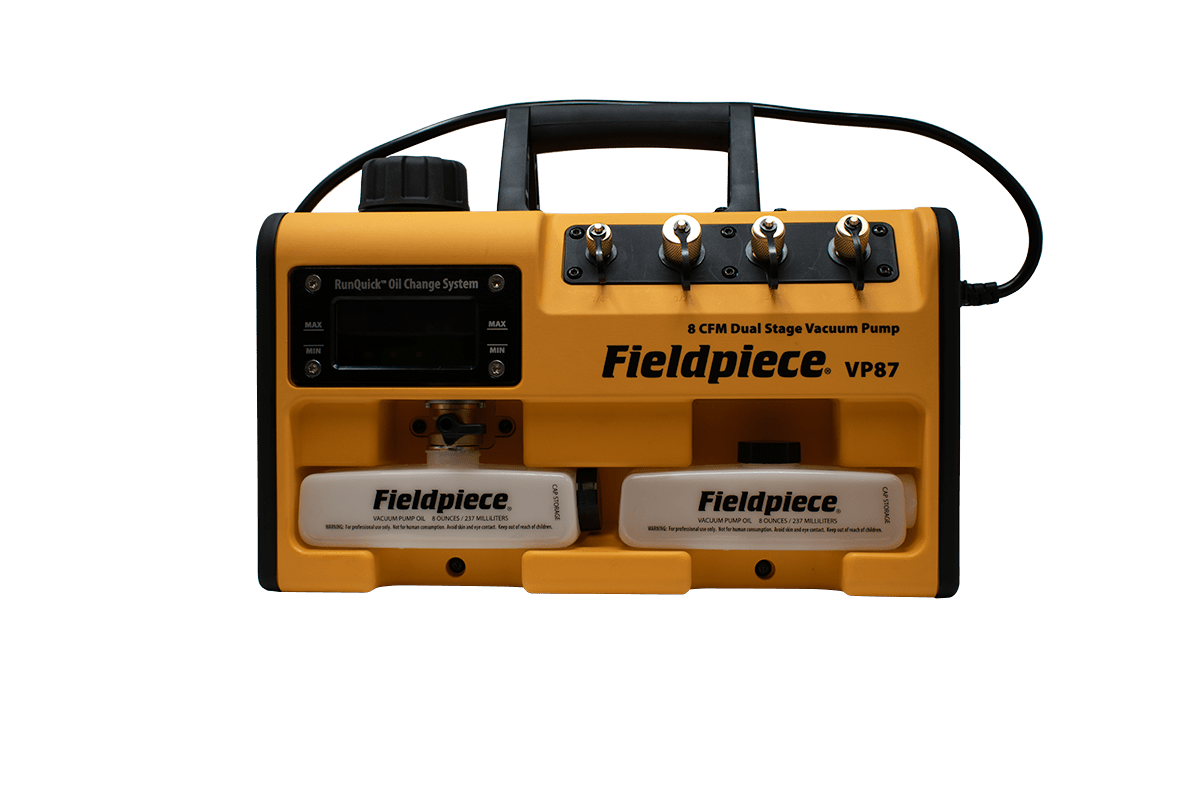

How a vacuum pump works

On a rotary vane vacuum pump, a motor turns a driveshaft. Connected to that driveshaft is the image pictured to the left.

1 (pump housing) is the wall of the compression chamber. This is made of a tough material capable of handling pressure.

If you have an oil pump, the inside wall is lined with a thin layer of oil.

If you have an oilless pump, the inside wall is usually lined with a carbon-based material.

2 (rotor) is connected to the driveshaft and spins clockwise or counterclockwise depending on your vacuum pump’s setup.

3 (vanes) are pressed along the sides of the pump’s housing by 4(spring) which pushes the vanes against the wall.

The vanes (3) are designed to compress the air in the chamber to a point where the air rushes out of the outlet valve and lower the pressure of the chamber to allow air from the system to rush in.

This all happens mechanically while the unit runs, which is why proper lubrication is important.

Why water is the enemy

Water and lubricants do not play well.

With an oilless vacuum pump, if water gets into the system the lubricant grabs onto it and creates a crud-like coating that will stop the pump from working.

With an oil pump, the water will slowly mix with oil causing performance to drop over time. Normally you will start to see the oil become milky.

Either way, water lowers performance making your startup time last longer and longer until your pump can’t hit the correct pressure.

The solution

So naturally, we all don’t want water to enter our vacuum pump so we use a few different techniques to rid the system of water.

The first is using a desiccant or water extraction device of some sort to collect the water before it makes it to the pump.

In our industry, we use a gas drying jar or a Pump Saver. both do the same thing but in different ways.

The second way is so unbelievably simple and yet, almost nobody does it.

Elevate. Your. Pump.

Seriously. Gravity is an amazing tool that everyone should be using. Just by having your vacuum pump above your pycnometer, you can add months of extra runtime to your pump.

We cannot stress this enough, and yet, the majority of labs we visit have their vacuum pumps tucked in a cabinet below everything.

If you use both methods to protect your vacuum pump, you can extend the lifespan of your pump and stop destroying them.